Screens

They are located in the first entrance structure of the treatment plant. Screens are used to remove coarse particles (such as paper, wood particles, nylon, fabric) in the wastewater given to the sewer.

It is designed in two ways as coarse and fine screen according to the opening between the screen bars. These screens are divided into two parts as manually cleaned or mechanically cleaned screens. Manual screens are mostly used in small flow wastewater treatment plants.

Mechanical screens are divided into linear mechanical screen and circular mechanical screen. Linear mechanical screens are used in high flow wastewater and in places with large screen channel depth. Circular mechanical screens are used in small and medium-sized wastewater flow rates. All screens can be made of stainless or black material. Screen dimensions are determined according to the wastewater flow rate and the channel depth is determined according to the wastewater sewage structure.

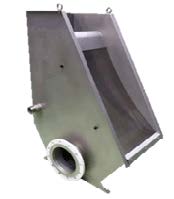

Static Sieve

In the physical treatment unit; It is an equipment with 0.5-3 mm sieve opening, which is designed to hold (paper fiber, plastic, etc.) solids in wastewater, which has no electrical components and is completely physically placed in the pump discharge line after coarse and/or fine screen. The sieve dimensions are determined according to the wastewater flow rate and the TSS value in the water.

It is very easy to install and the wastewater inlet is from the upper part and the outlet is from the lower part. The body of the static sieve is made of stainless or black material, and the sieve part is made of stainless material. No maintenance cost is required.

Drum Sieve

It is designed to hold (paper fiber, plastic, etc.) solids with 0.5-3 mm sieve opening placed in the pump discharge line after coarse and/or fine screen in the physical treatment unit. In the drum sieve, which is of the external flow type, the diameter and length of the drum are determined according to the wastewater flow rate and the TSS value in the water

The body of the drum is made of stainless or black material, and the sieve part is made of stainless material. There are washing nozzles inside the drum to prevent clogging between the sieves. The sieve part of the rotating drum, which is connected to the motor-reducer, is washed by the nozzles.

Disc Sieve

In the physical treatment unit, there are two types of applications disc sieves, which have much more efficient solids retention than static sieves and drum sieves. The disc sieve used after coarse and/or fine screen is designed to hold solid materials with 100-2000 micron sieve opening (paper fiber, plastic, etc.).

Due to its high filtering efficiency, it can be used in paper, textile, food, etc. It is preferred in many sectors.

Depending on the motor-reducer, the rotating disc sieve is operated depending on the water level or time, it is a fully automatic equipment that operates without the need for personnel, by washing the discs with nozzles periodically to prevent clogging in the sieve part. The disc sieve body is made of stainless or black material, and the sieve part is made of stainless material.

Oil Separator

The solids in the waste water precipitate and become oil, grease etc. floating substances, are held on the surface and separated from the water. No environmental problems will be encountered in the wastewater that will be given to the sewerage or the receiving environment.

Gas stations, auto repair shops, restaurants, cafeterias etc. Preferred grease traps for places are manufactured as St 37 epox painted carbon steel or stainless steel.

Quick Mixer

Mixers are used both in chemical solution preparation processes and in chemical treatment and sludge dewatering units in order to provide a homogeneous mixture of the chemical dosed into the wastewater.

The mixers used in the processes are designed depending on the geometry of the place of use, the viscosity of the fluid, and the solubility of the chemical in order to provide a complete mixture.

It is manufactured to consist of motor-reducer shaft and propeller.

Slow Mixer

It is the conversion of the flocs formed as a result of chemical reactions into large flocs that can settle with the addition of polyelectrolyte and slow mixing. The homogeneous distribution of the solutions in the wastewater is provided by a paddle type mixer.

Mixers used in processes are designed depending on the geometry of the place of use, the viscosity of the liquid and the solubility of the chemical to provide a complete mixture.

It is manufactured to consist of motor-reducer shaft and pallets.

Circular Scraper

The purpose of this scraper is to properly scrape the sludge accumulated on the pool floor and ensure that it is collected in the desired area. In circular settling ponds, wastewater inflow is from the center. The mud in the water moving towards the weirs begins to settle to the bottom. The sludge that settles to the bottom is brought to the conical part of the bottom with a scraper and separated from the water. Circular settling scrapers; It consists of the central bearing, half traveling bridge, floor scraper pallets, surface foam scraper and foam weir and a weir outlet system that discharges the treated water. The equipment can be made of stainless or black material.

Linear Scraper

The purpose of this scraper is to collect the sludge accumulating on the pool floor and the oil, mud and other floating materials accumulating on the surface. These pools are designed in a rectangular style. The pool floors are flat and there is a bottom scraper and a suction pump to take the sludge settling on the bottom. Bottom scraper and surface scraper are connected to a traveling bridge on the side concrete of the pool. The equipment can be made of stainless or black material.

Chain superficial scraper

The purpose of this scraper is to remove the oil, suspended solids and other floating materials accumulated on the surface of the pool from the water by scraping them from the surface. These pools are designed in a rectangular style. Surface scraping is done by moving the pallets connected to the chain in one direction. It is ensured that all floating materials accumulated on the pallets connected to the chain moved by the motor reducer group on the rail in the side concrete of the pool are transferred from the scraping ramp to the collection reservoir. The equipment can be made of stainless or black material.

Filter press

The sludge separated from the water under high pressure between the filter press plates is converted into cake. After the filter press plates are filled, the sludge inlet is cut and the process of removing the sludge cakes from the press begins. Filter press is a sludge dewatering equipment with the highest sludge dry matter ratio.

Sludge Thickener

It is ensured that the sludge taken into the sludge condensation pool is increased in sludge density at the bottom of the pool before dewatering and a clear water layer is present in the upper part. The structure consisting of a motor reducer that provides the mixture, the deflector structure that prevents the mixing at the top of the condensation pool, where the slurry enters, vertical bars that make the mud mixture in the middle of the pool, the bottom scraper that brings the sludge with increased density at the bottom to the middle of the pool and the outlet weir structure that takes the clear water out of the pool.

Automatic Polyelectrolyte Preparation Unit

The polyelectrolyte preparation unit has three chambers. Since each chamber is independent of each other, the first two chambers are constantly full and the third chamber is full and empty. When it is empty, it starts the water inlet depending on the level float and when it is full, it cuts it off. Since the first two chambers are for preparation purposes, there is a mixer in each. The third chamber is for dosing purposes and is the part where the dosing pump sucks.